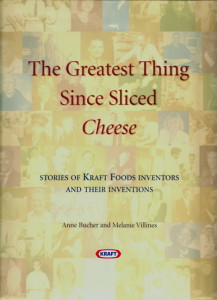

The Greatest Thing Since Sliced Cheese

Published by: Kraft Food Holdings

How do you condense 50 years of some of the most creative and innovative products into a keepsake book that is manageable in size? This was the challenge for two senior Kraft employees to commemorate the 50th anniversary of the Technology Center in Glenview, Illinois. Here’s how it went:

- In 1998 Kraft Foods Inc. celebrates the 50th anniversary of the technology center with festivities. Two senior staff members, Ann Bucher and Miranda Miller, volunteer to prepare a display of some of the patents and inventions that were born from the Center.

- They begin researching the archives and by interviewing some of the old time inventors and found that a display would only scratch the surface of the rich history of innovation and the idea for a book was launched.

- This extensive research takes the next seven years to complete. A seasoned designer, Connie Scanlon of Bogfire Inc., is engaged to begin the process of collating, designing and laying out the book from the large amount of gathered material.

- Connie Scanlon consults with InterPress staff for details of manufacturing. Paper weights and type, printing specifi

cs, case material, binding options and production lead time are all discussed in the initial consultation.

cs, case material, binding options and production lead time are all discussed in the initial consultation. - Kraft requests a budget quote from InterPress for a 650 page coffee table book.

- After viewing a dummy sample book made by InterPress, Kraft and the designer decide that 650 pages is too thick a book and reduce the number of pages to 524 after additional editing is done.

- InterPress begins the lengthy process of proofing using wet proofs, the most accurate proofing method. Printing of old, restored photos is a challenge for any printer and often the dpi is not adequate for sharp, clear reproduction. The production department at InterPress took up the challenge allowing for multiple rounds of proofs to ensure the excellent quality needed for this All-American keepsake.

- InterPress staff help to formulate the final specifications including a round backed spine which will allow the book to open flat with the large book- Matching head and tail bands and a nice matte paper are chosen. Final copies will be individually shrink wrapped.

- Wet proofs are done using a proofing press and sent to the designer for approval. Multiple rounds of proofs are submitted after color corrections are made by the designer. Read more